Agri Technovation's Picklogger

Objective & Design

We were tasked to overhaul the original Picklogger (completed a few years earlier by another engineer) to improve it produceability and performance. A major issue with the orignal version was the price and availability of the microcontrollers used. The old version used an Atmel ATSAMD21G18A which, at the time of writing, is unavailable and costs R66 each (at a purchase quantity of 2500pcs). We chose to use a modern STM32G030F6P6 microcontroller (R8 per device at a purchase quantity of 1000pcs) with an accompanying external Winbond W25X10CL flash chip (R4 per device at a purchase quantity of 1000pcs) for a combined price of R12. This is 18% of the initial microcontrollers price. The substantial price reduction paired with vastly better availability was a game changer for the customer.

My role in this project was to rewrite the firmware (from the ground up). Due to the much smaller flash storage on the new STM32 microcontroller (32KB vs 256KB) a lot of time was spent trying to cram all of the required code into the limited space. This limitation also led me to interface directly with the device's registers to save space (instead of using the relatively space-hungry HAL libraries).

Another challenging portion of the development was maximising the number of cuts that can be stored on the external flash. I managed to squeeze 34816 cuts into the flash chip's capacity of 1Mb or 0.125MB (for the tech challenged out there, you would only be able to store ~1/20th of a photo on it). By using an external flash chip we can also easily upgrade this to much larger capacities, although this should not be necessary.

My role in this project was to rewrite the firmware (from the ground up). Due to the much smaller flash storage on the new STM32 microcontroller (32KB vs 256KB) a lot of time was spent trying to cram all of the required code into the limited space. This limitation also led me to interface directly with the device's registers to save space (instead of using the relatively space-hungry HAL libraries).

Another challenging portion of the development was maximising the number of cuts that can be stored on the external flash. I managed to squeeze 34816 cuts into the flash chip's capacity of 1Mb or 0.125MB (for the tech challenged out there, you would only be able to store ~1/20th of a photo on it). By using an external flash chip we can also easily upgrade this to much larger capacities, although this should not be necessary.

A Picklogger attached to a pair of citrus scissors.

Basic Functionality

The Picklogger can be attached to most standard harvesting scissors. When the operator cuts a stem a magnet attached to one of the device's movable arms is brought into proximity of the PCB within the device. A Hall effect sensor detects this and a 'cut' is stored.

A 'cut' is composed of the following data:

A 'cut' is composed of the following data:

A harvester using a Picklogger-equiped pair of harvesting scissors.

- The current time (received from the GPS satellites).

- The current latitude.

- The current longitude.

- The current GPS signal quality.

- The current battery voltage.

Avocado harvesters with Pickloggers in the USA.

Data

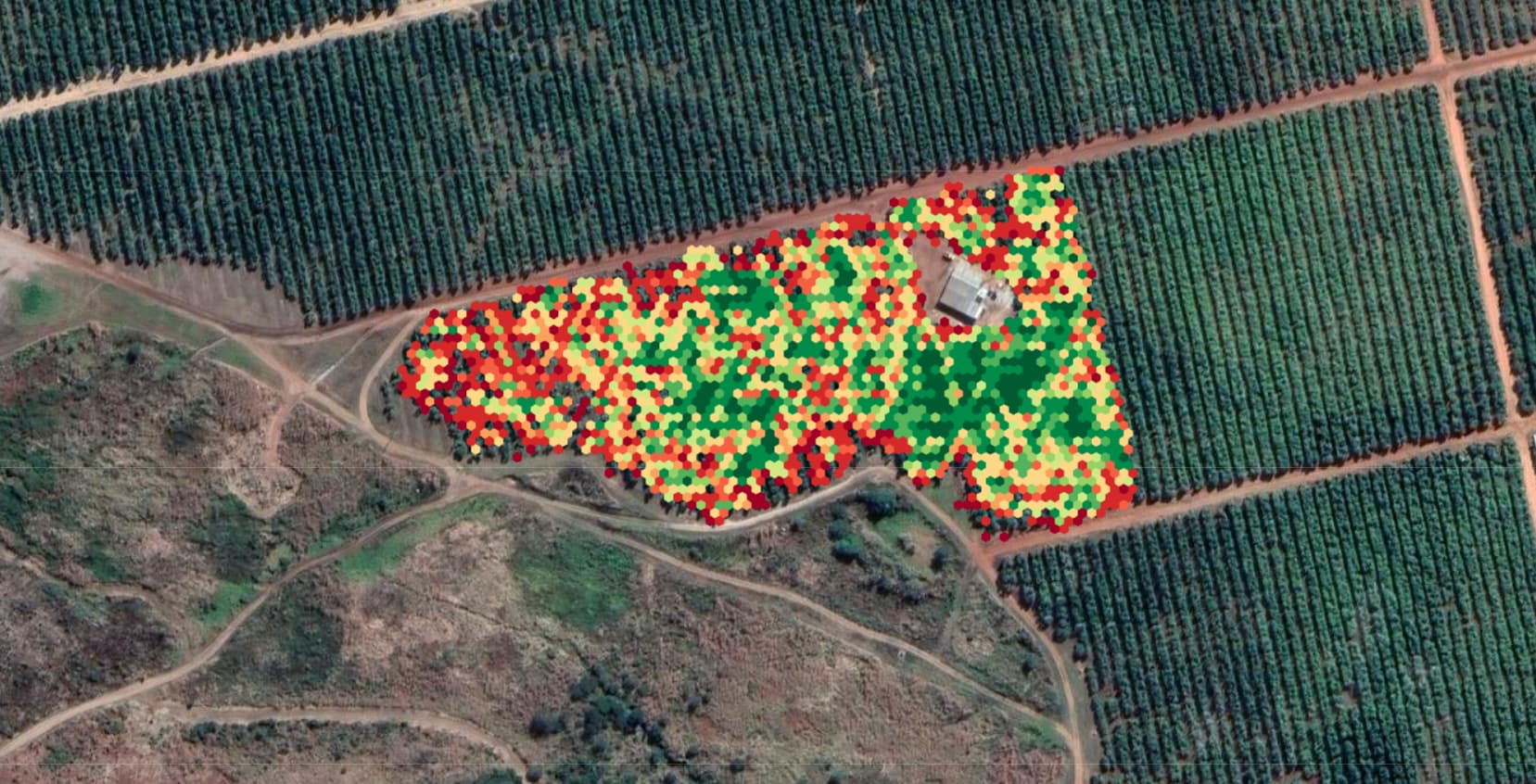

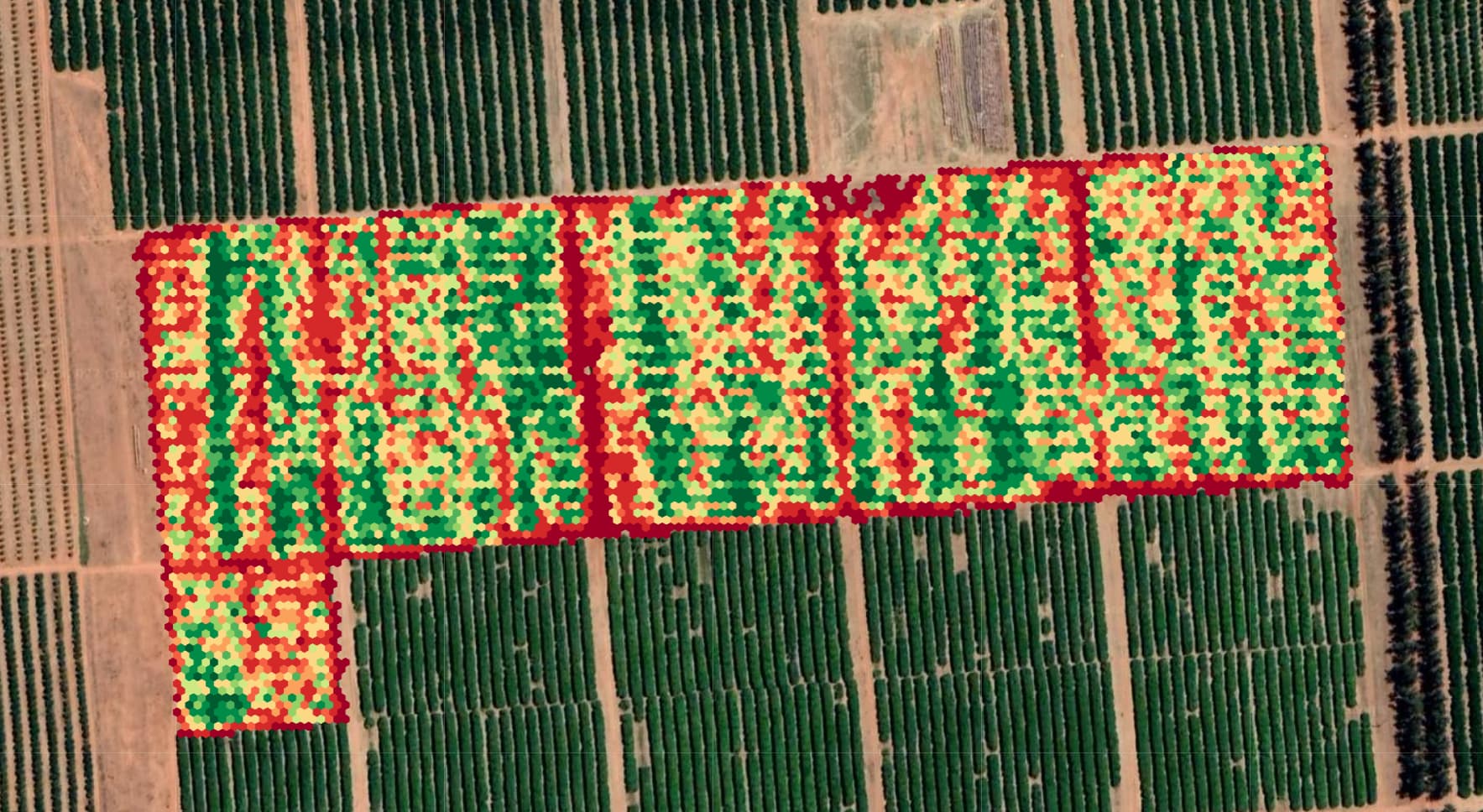

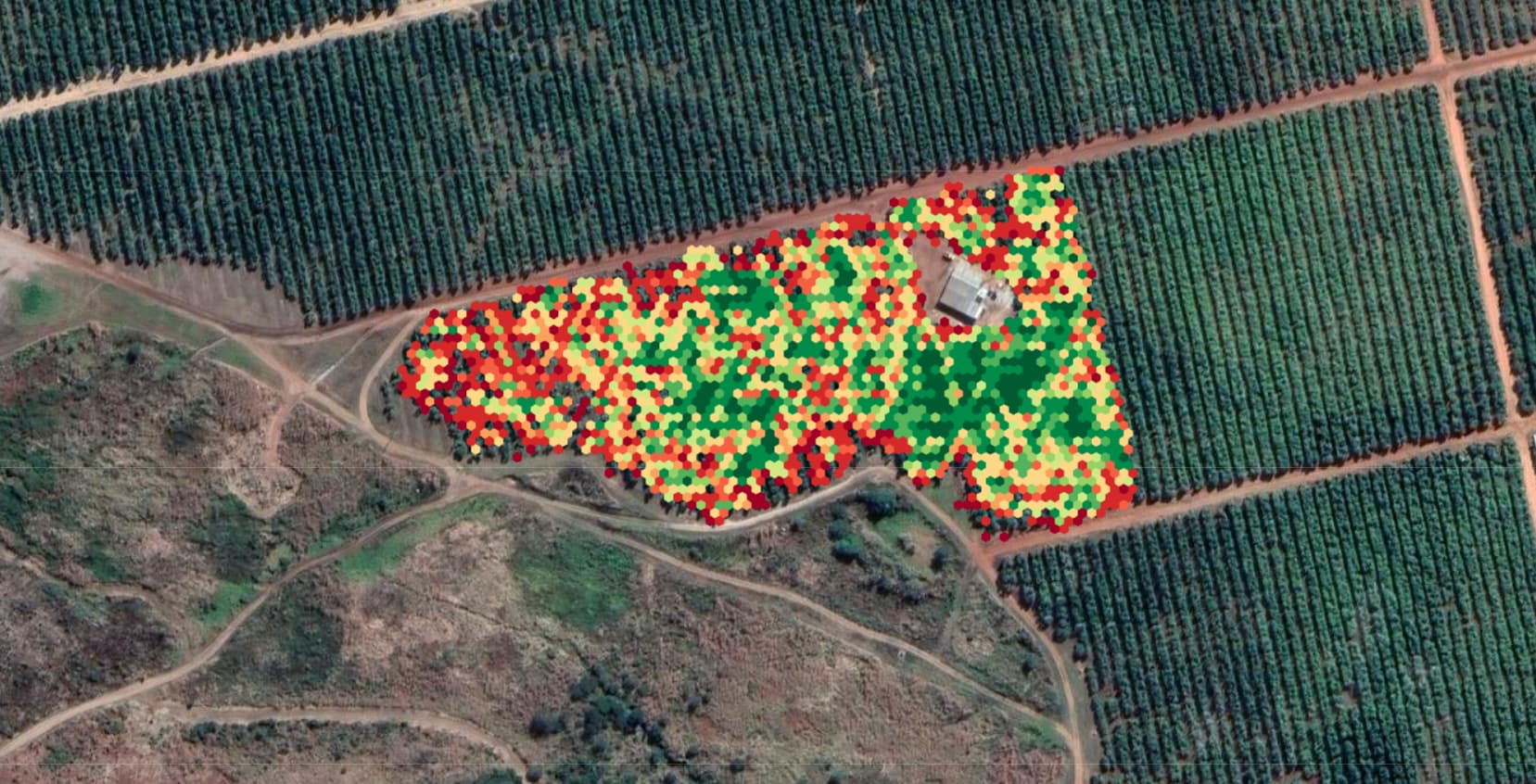

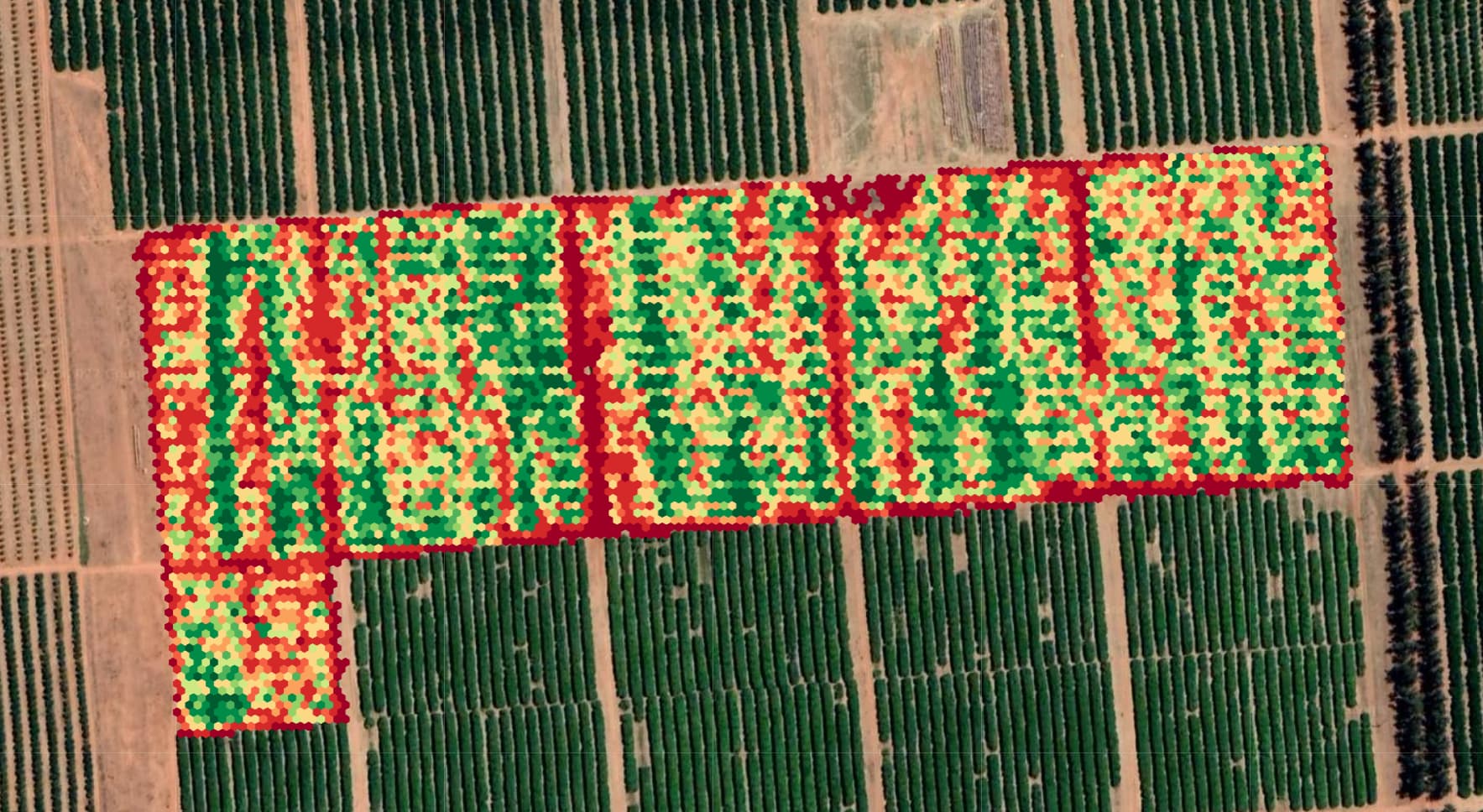

When the farmer visits the web dashboard he can visualise his farm's pick density as an overlay on a map. The areas of high yield are indicated in green and areas of very low yield are indicated in red. From this visual data, the farmer can decide where to fertilize during the next season. This fertilizer can be provided by Agri Technovation (this is where they make a profit, not from the Picklogger directly).